parker series gear used in parkers gear pumps, including P20, P30, P31, P50, P51, P75, P76, P315, P330, P350, P365, our P Series gear can be 100% interchanged with Parker Commercial P series pump.

P21

312-0100-002, 21/31 SPACER FOR CONTINENTAL SHAFT, TB-1669

312-1000-200, 21/31 CONTINENTAL SHAFT, 5/8 -9 TOOTH, AI-1135

312-1133-002, 30 TO 30 PIGGYBACK CONNECTING SHAFT, AF1133

312-1133-003, 30 TO 50 PIGGYBACK CONNECTING SHAFT, AD1133

312-1135-133, 21/31 CONTINENTAL SHAFT 1-1/4″-14 TOOTH, AH-1135

312-1135-138, 21/31 CONTINENTAL SHAFT 7/8-13 TOOTH, AJ-1135

312-1135-152, 21/31 CONTINENTAL SHAFT 3/4″ KEYED, AV-1135

312-1500-400, 21/31 CONTINENTAL SHAFT 1″ KEYED, ED-1135

391-1781-021, KEY FOR 1″ SHAFT, X10-13 (1/4X3/8X1-1/2)

391-1781-045, KEY FOR 1-1/4″ SHAFT, X10-38, (5/16X15/32X1-1/2)

391-2082-071, 21,315 DOWEL PIN

391-2286-004, PLUG, T1391 391-2585-006, 31 RING SEAL, LB-1669-1

391-2685-011, 21/31 SNAP RING FOR CONTINENTAL SHAFT, X97-100

391-2686-063, 21/31/330 SHAFT BEARING SNAP RING, (SPIROLOX) X134-206

391-2882-051, 31/51, THRUST PLATE POCKET SEAL STRIP

391-2883-058, 21/31 PUMP SHAFT SEAL, INTEGRAL, X73-37-16

391-2883-107, 21/31/330 PUMP SHAFT SEAL CONTINENTAL, X73-37-18

391-2883-119, 21/31/M330 MOTOR SHAFT SEAL, INTEGRAL, X73-50-9

391-2883-126, 21/31/M330 MOTOR SHAFT SEAL, CONTINENTAL, X73-50-11

391-2884-019, 21 BODY GASKET, UB-3006-239

391-3381-040, 21/31 SEAL RETAINER, AE-166

P25

391-2686-065, 25/51/350 SHAFT BEARING SNAP RING, (SPIROLOX) X134-283

391-2882-051, 31/51, THRUST PLATE POCKET SEAL STRIP

391-2883-096, C101/25 MOTOR SHAFT SEAL, X73-50-3

391-2884-021, 25/51/M350 BODY GASKET, UB-3006-244

391-3681-001, CHECK VALVE, M1391K

391-3784-028, 5/8″ FLAT WASHER

P30 P31

391-1401-025, 5/8″ BOLT, 5″ 391-1401-089, 5/8″ BOLT, 5-1/2″

391-1401-095, 5/8″ BOLT, 5-3/4″ 391-1401-090, 5/8″ BOLT, 6-1/2″

391-1401-111, 5/8″ BOLT, 7″ 312-0100-002, 21/31 SPACER FOR CONTINENTAL SHAFT, TB-1669

312-1135-133, 21/31 CONTINENTAL SHAFT 1-1/4″-14 TOOTH, AH-1135

312-1135-138, 21/31 CONTINENTAL SHAFT 7/8-13 TOOTH, AJ-1135

312-1135-152, 21/31 CONTINENTAL SHAFT 3/4″ KEYED, AV-1135

312-1500-400, 21/31 CONTINENTAL SHAFT 1″ KEYED, ED-1135

P37

391-1471-051, 1/2″ NUTS 391-2286-004, PLUG, T1391

391-2883-052, 37/76/P365 PUMP SHAFT SEAL, X73-37-10

391-2883-094, 75 MOTOR SHAFT SEAL, X73-50-1

391-3681-001, CHECK VALVE, M1391K

391-3782-132, 1/2″ FLAT WASHERS

P50 P51

391-1401-025, 5/8″ BOLT, 5″ 391-1401-089, 5/8″ BOLT, 5-1/2″

391-1401-095, 5/8″ BOLT, 5-3/4″ 391-1401-090, 5/8″ BOLT, 6-1/2″

391-1401-111, 5/8″ BOLT, 7″ 313-1133-001, 51 CONNECTING SHAFT, YA-1133

50-SHFTBRG — 391-0381-077; X69-58; 6306-2RS-20

313-1000-300, 51 CONTINENTAL SHAFT 7/8-13 TOOTH, AD-1135

313-1135-194, 51 CONTINENTAL SHAFT 1-4″-14 TOOTH, AG-1135

313-1500-400, 51 CONTINENTAL SHAFT 1″ KEYED, AE-1135

391-1451-076, 5/8″ NUTS

391-1781-021, KEY FOR 1″ SHAFT, X10-13 (1/4X3/8X1-1/2)

391-1781-045, KEY FOR 1-1/4″ SHAFT, X10-38, (5/16X15/32X1-1/2)

391-2082-032, 31/330/51/350 DOWEL PIN, X10-99

391-2286-004, PLUG, T1391

391-2585-009, 51 RING SEAL, NB-1669-1

391-2686-065, 25/51/350 SHAFT BEARING SNAP RING, (SPIROLOX) X134-283

391-2882-051, 31/51, THRUST PLATE POCKET SEAL STRIP

P75 P76

5/8 X 127 — 391-1401-025, 5/8″ BOLT, 5″

316-1135-147, 76 CONTINENTAL SHAFT 1-1/4″ KEYED, AL-1135

316-1135-148, 76 CONTINENTAL SHAFT 1-1/4″-14 TOOTH, AS-1135

391-1451-076, 5/8″ NUTS

391-1781-045, KEY FOR 1-1/4″ SHAFT, X10-38, (5/16X15/32X1-1/2)

391-2082-033, 76 DOWEL PIN, SOLID, X10-98

391-2286-004, PLUG, T1391

391-2584-051, 76 SEAL RETAINER, RA-1072

391-2585-011, 76 RING SEAL, WB-1669-1

391-2686-025, 76 SHAFT BEARING SNAP RING, X96-315

391-2881-457, 76 SEAL RETAINER O’RING, L-3006-47

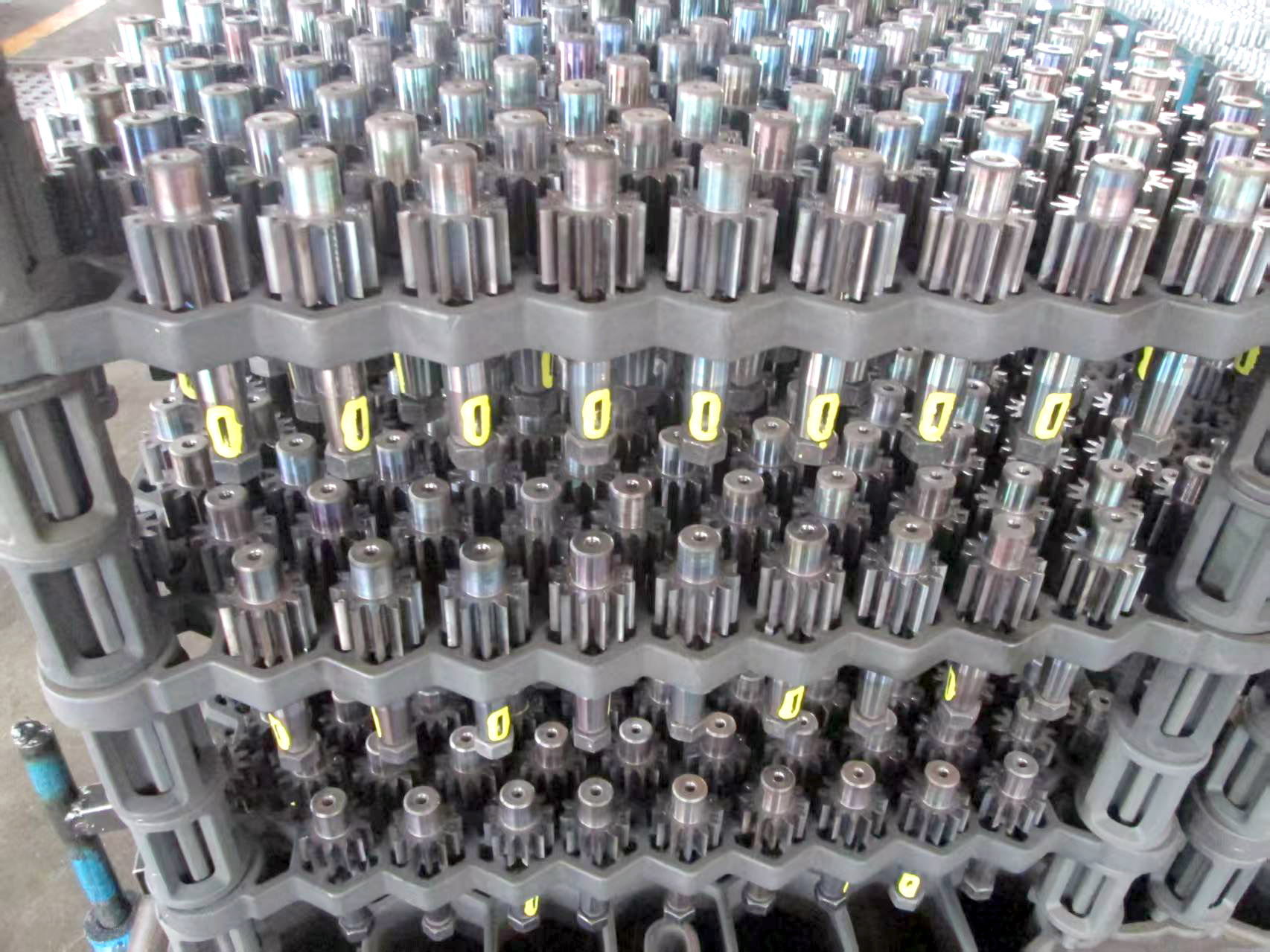

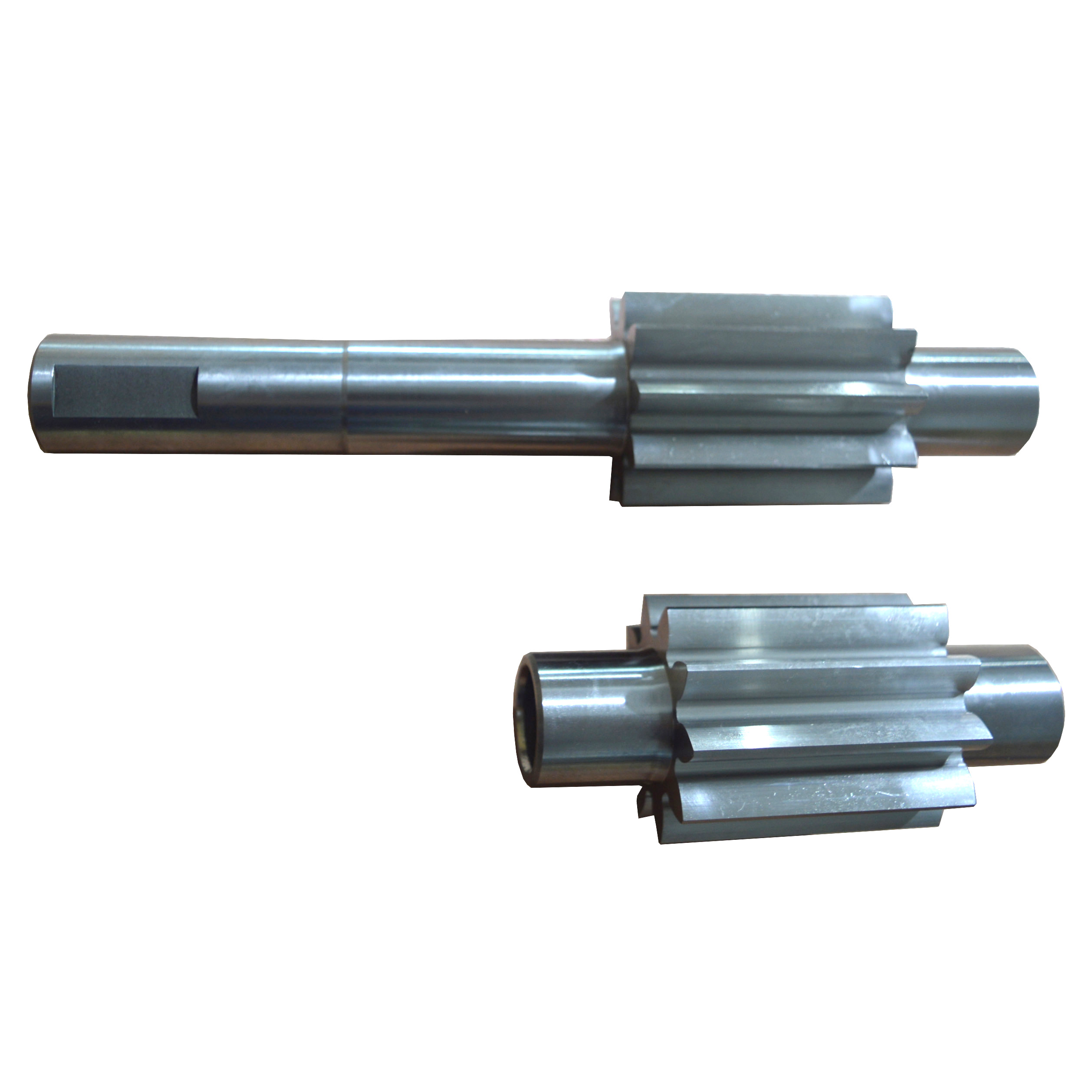

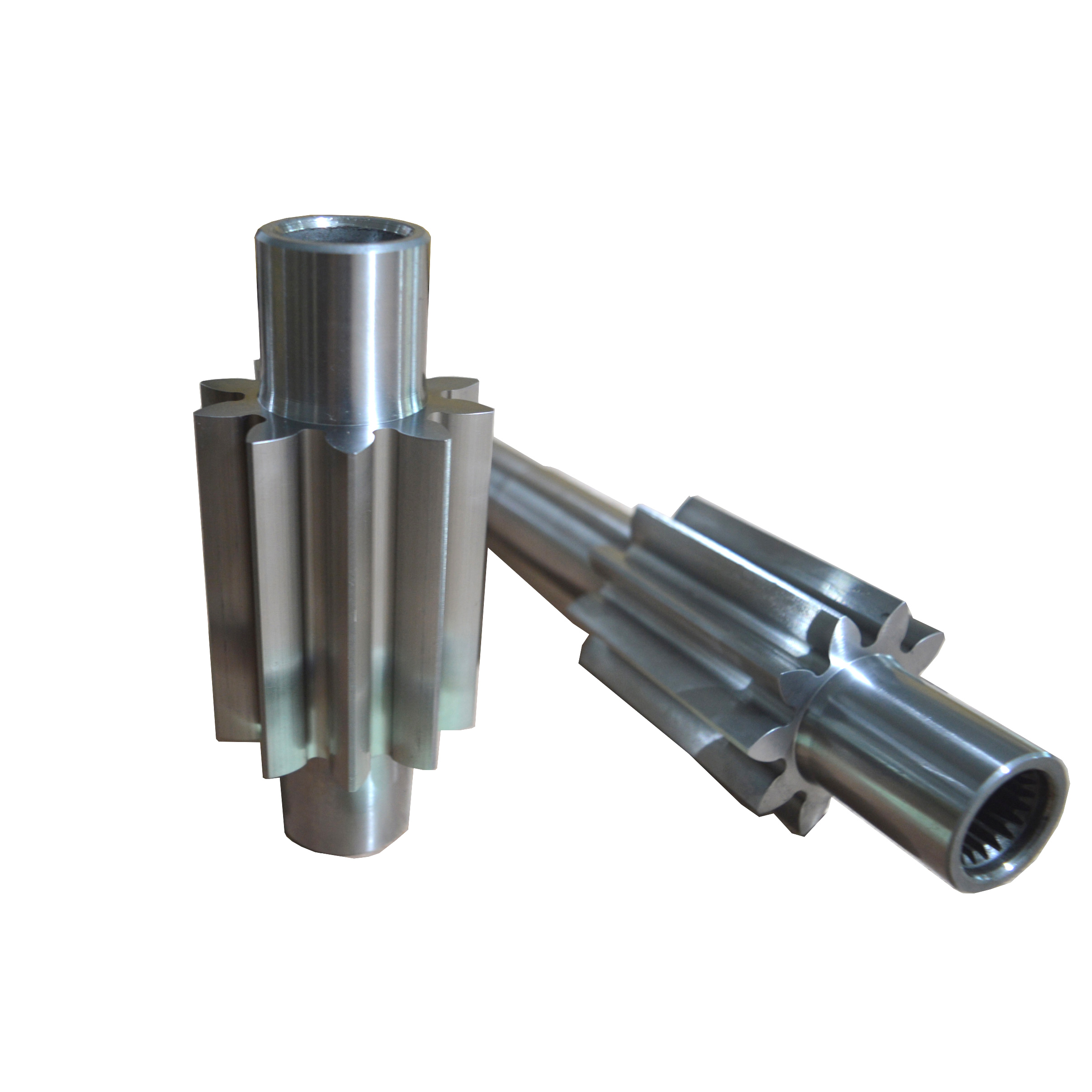

Key Features of parker gear

material: 8620H/ 20CrMnTi Spline Types: Involute Splines/Straight Splines

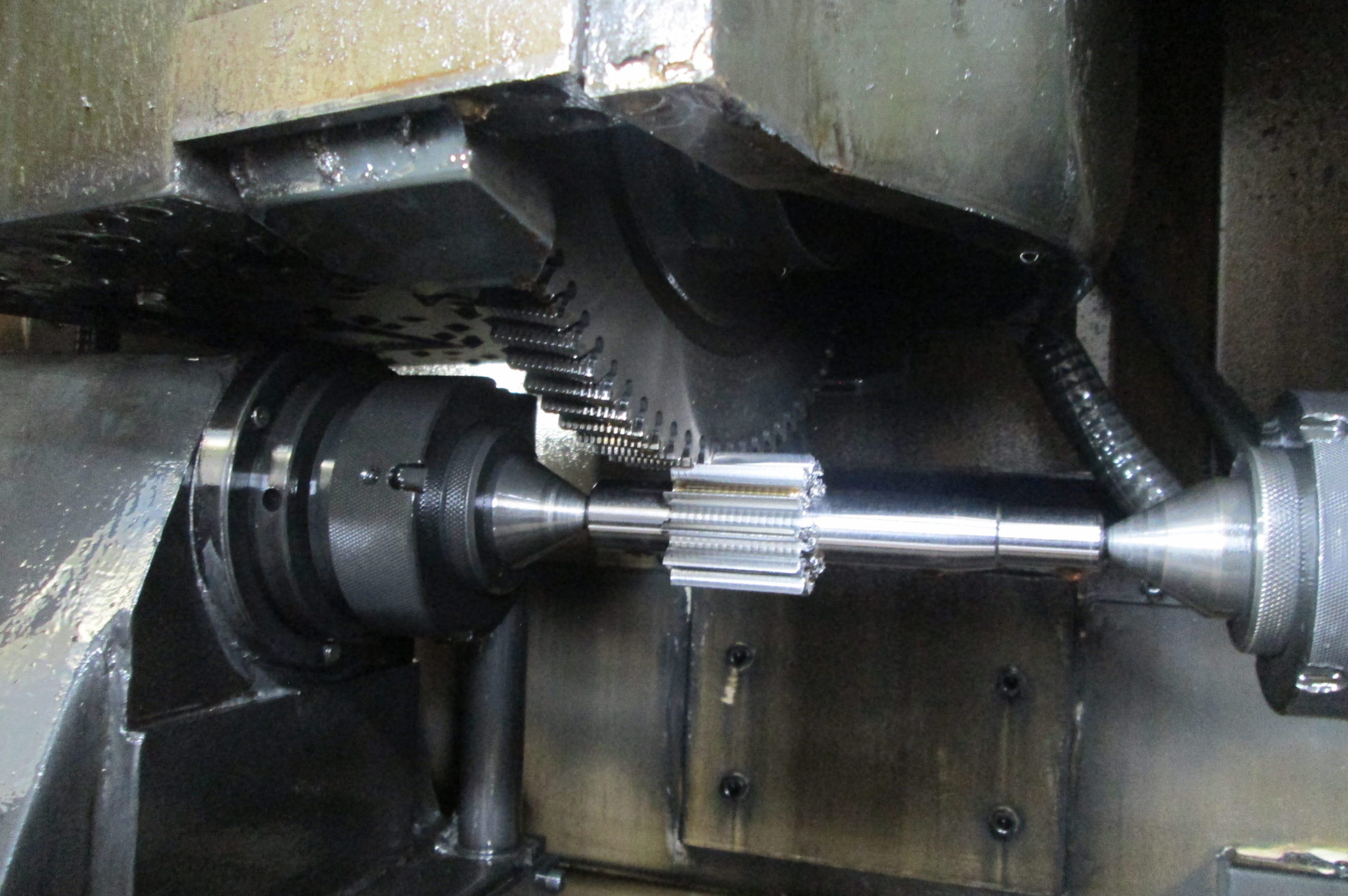

Machining method: torneamento, heating and hobbing

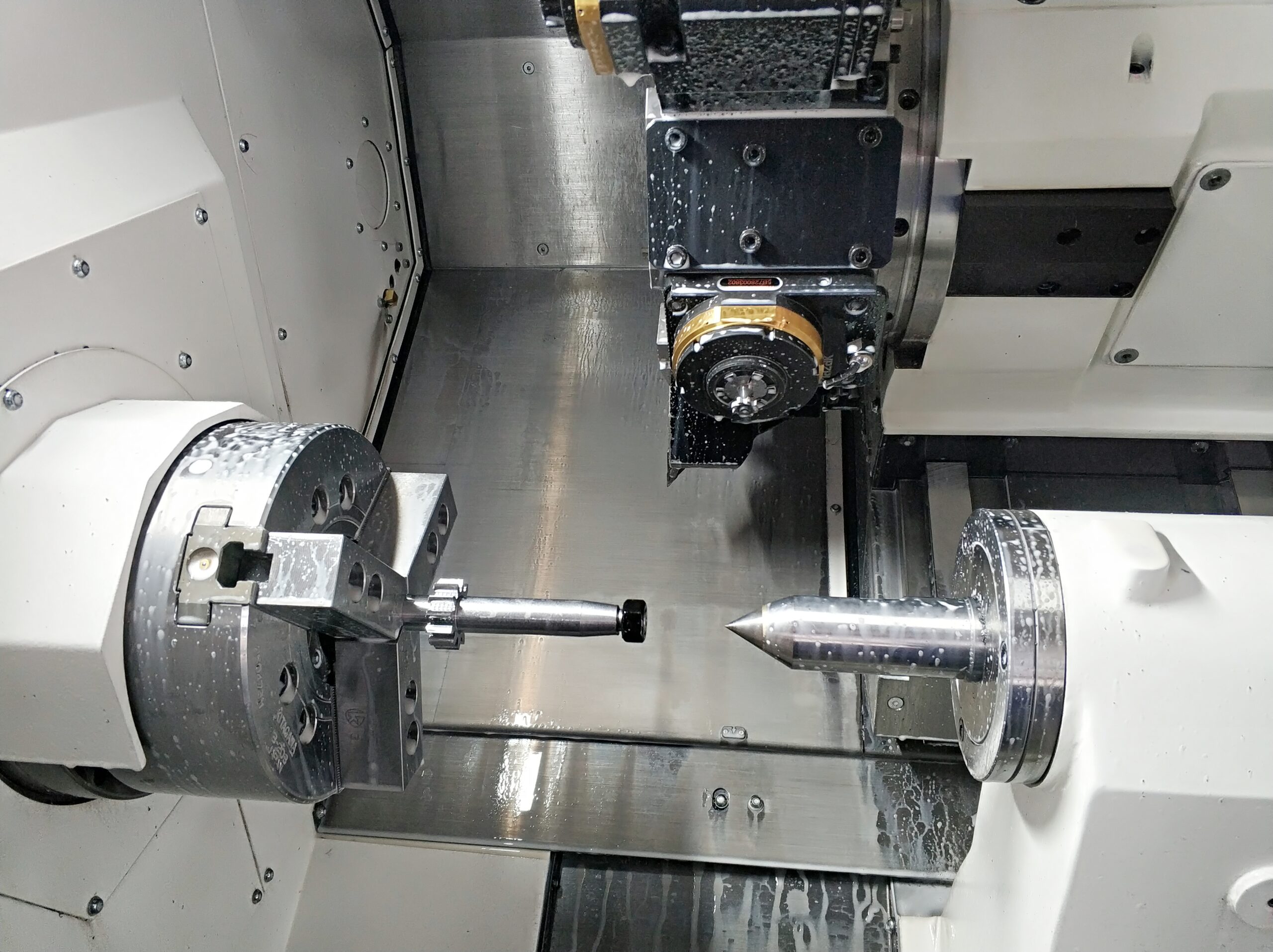

Turning: CNC turning machine, get a specific dimension and fine surface.

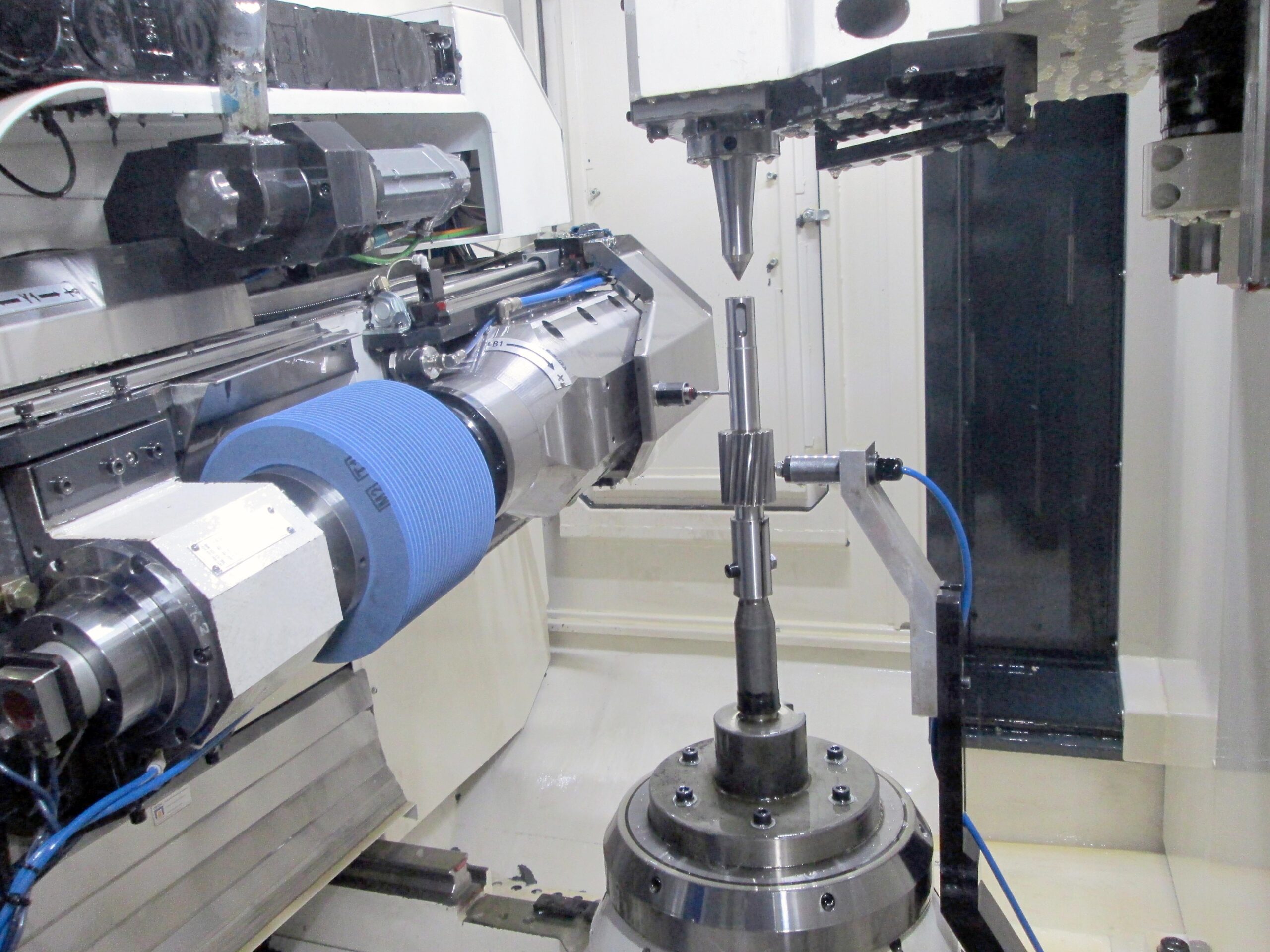

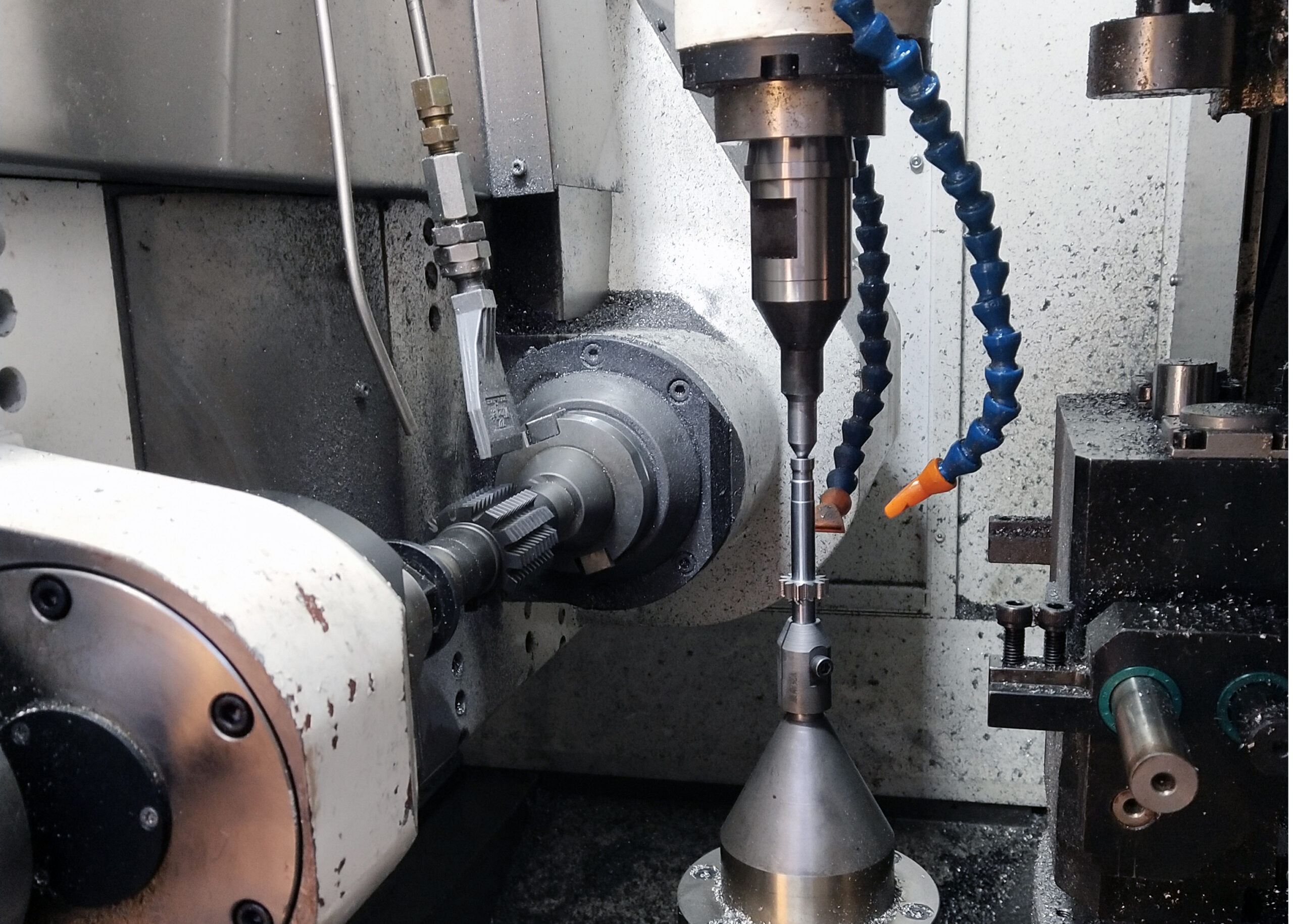

Gear hobbing: is a gear manufacturing method to cut teeth into the blank with a hob, all of our hobbing and shaving are automatic, make sure high accuracy of teeth profile and lead.

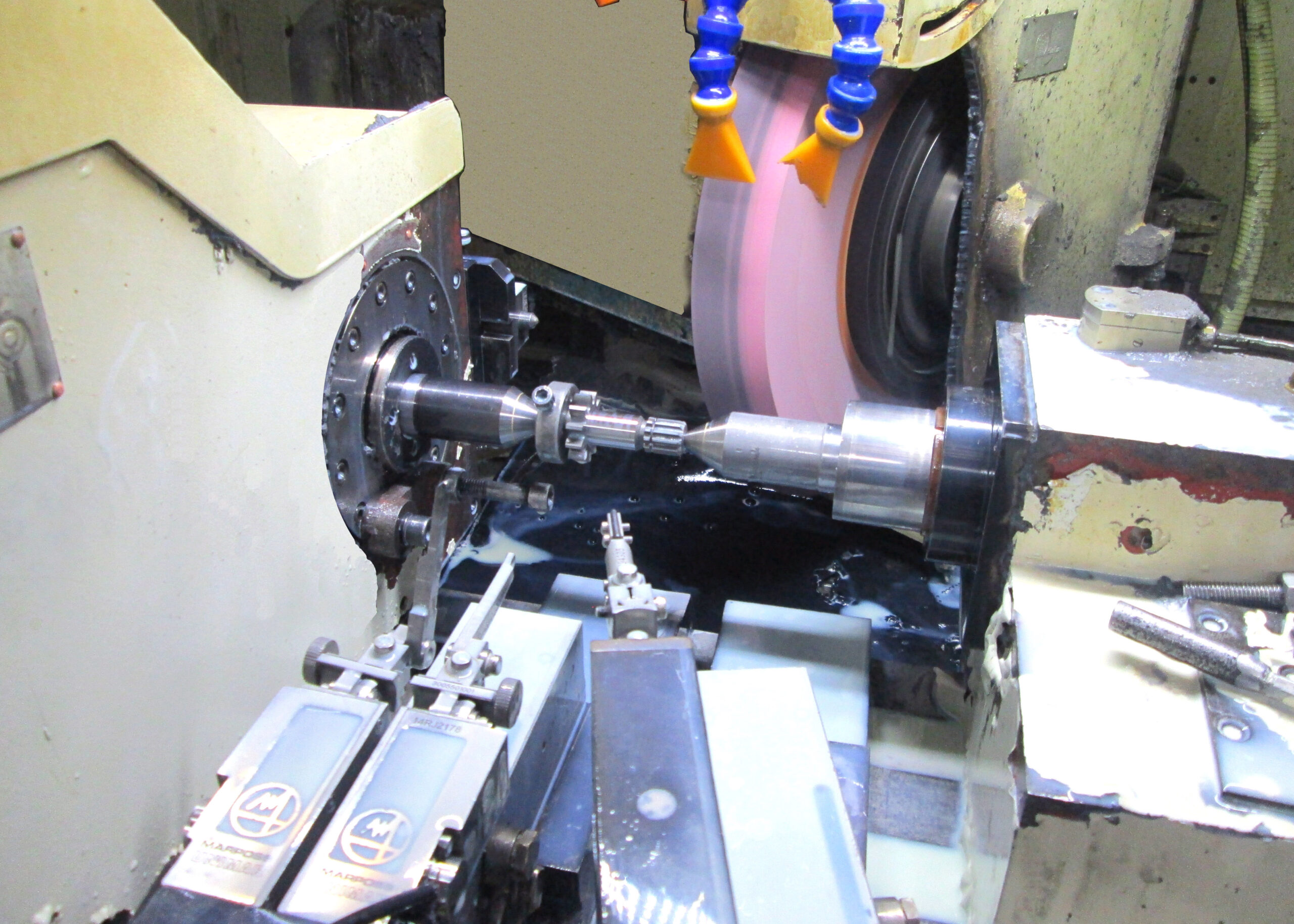

Gear shaving: removes small amounts of metal from the working surfaces of gear teeth. corrigir erros no índice, ângulo helicoidal, perfil do dente. O processo de raspagem dos dentes também pode melhorar o acabamento da superfície do dente. O barbear fornece modificações de forma que reduzem o ruído da engrenagem. Essas modificações também podem aumentar a segurança e a vida útil do equipamento.

Gear heat treatment: a critical step in gear manufacturing to enhance hardness, strength, wear resistance.

Technical demand:Carburizing and quenching, dureza 58-64 HRC, case depth 0.6-1.0mm

Moagem de engrenagens: Gear grinding is a precision machining process used to improve the surface finish, accuracy, and durability of gears.

Gear testing: Gear inspection ensures quality, accuracy, and performance by verifying dimensional tolerances, tooth geometry, surface finish, and hardness.

| Tooth Profile | Ensures correct involute shape for smooth meshing |

| Pitch Accuracy | Affects gear engagement and noise levels |

| Runout | Checks eccentricity and alignment errors |

| Surface Finish | Impacts wear resistance and fatigue life |

| Dureza & Case Depth | Verifies |