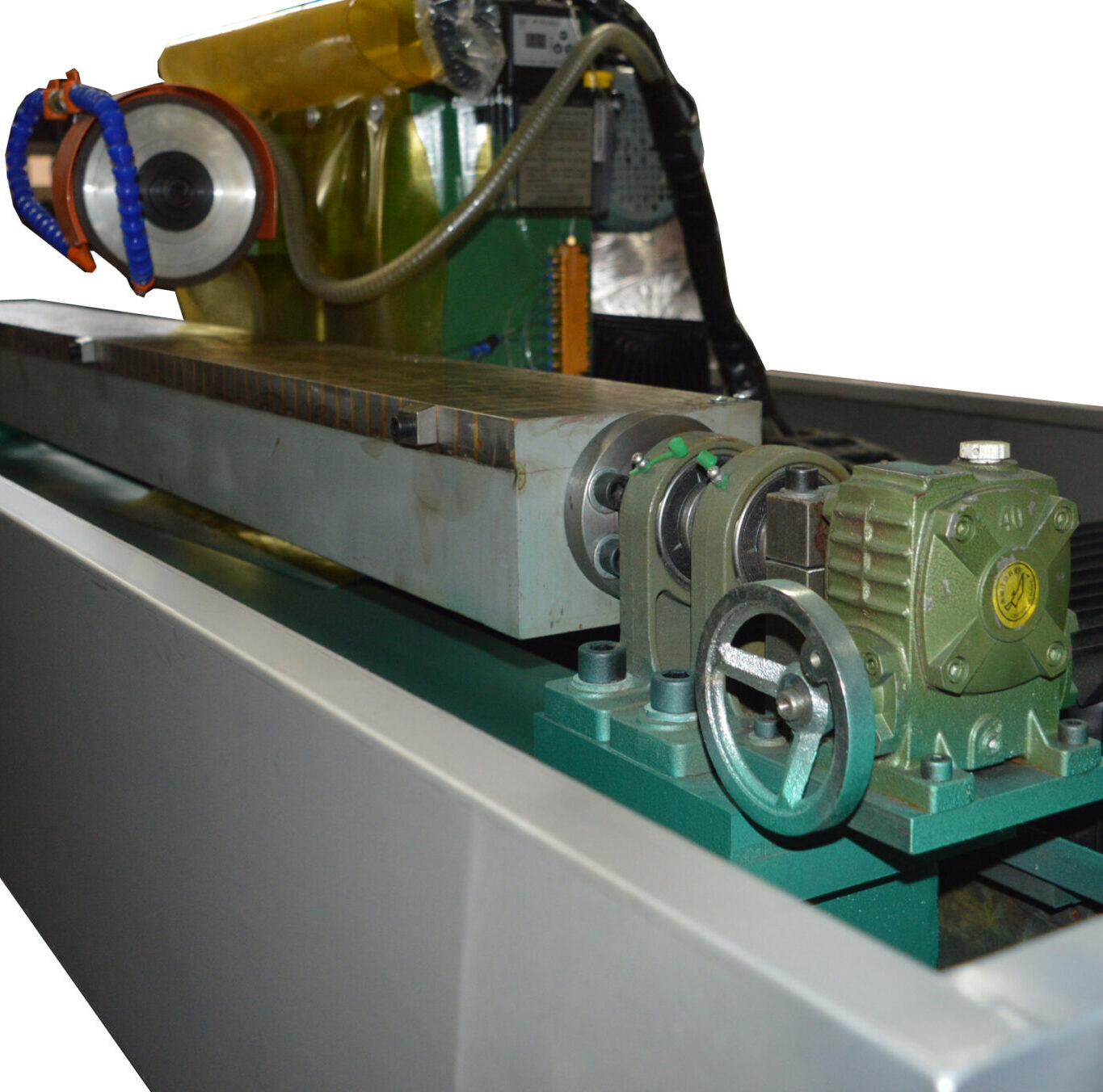

Structure feature:High precision grinding, advanced practical serrated knife grinder, widely used in serrated blade series;suitable for printing, packaging, papel, plástico, leather, cutter machinery and other industries serrated knife, can be used for grinding and cutting; incógnita, y, z three coordinate CNC system; feed knife using high precision ball wire rod, riel de guía lineal, by driving the grinding wheel to achieve the effect of knife grinding; special grinding head motor with high strength, sufficient power, huso, motor through frequency conversion can change the spindle rotation speed, improve the sharpness and roughness of the knife. electromagnet table have a angle adjustable device(0-90°),easy to operate, can grinding various knife. Teeth space can be set in the program as demand; according the sand wheel thickness, teeth space setting 0.5-25mm. grinding Knife process length 600mm;( we can make larger machine,the max length can be 3000mm)

| 1600 máquina de molienda de cuchillos dentados Data | |

| grinding max length | 1600mm |

| Vertical travel of the workbench | 1600mm |

| Workbench horizontal travel ( up and down) |

150mm/120mm |

| grinding head max speed | 6000rpm |

| potencia del motor del cabezal de molienda | 380V 50HZ 2.2KW |

| grinding wheel size (larger wheel dia. need lower speed) |

Φ150/160/180/200/250*32*20mm |

| weight | 1650Kg |

| whole machine size | 2800*1100*2000 |

A serrated knife grinding machine is a specialized piece of equipment designed to sharpen the unique, scalloped edges of serrated knives. These knives have small, tooth-like indentations along the blade, which require a different sharpening approach compared to straight-edged knives. Here’s an overview of what such a machine might entail:

Características clave de un Serrated Knife Grinding Machine:

- Specialized Grinding Wheels or Stones: The machine typically uses thin, tapered grinding wheels or stones that can fit into the small serrations to sharpen each individual tooth.

- Ángulos ajustables: It allows for precise angle adjustments to match the original serration angle of the knife, ensuring consistent sharpening.

- Automated and Manual Operation: it’s fully automated grinding when you adjusted the teeth data.

- Durability and Precision: High-quality materials and construction ensure the machine can handle the repetitive task of sharpening serrated edges without losing precision.

- Características de seguridad: grinding motor and guides designed to protect the user and ensure the knife is held securely during sharpening.