Engranajes de la serie Parker utilizados en bombas de engranajes Parkers., incluyendo P20, P30, P31, P50, P51, P75, P76, P315, P330, P350, P365, Nuestro equipo Serie P puede ser 100% intercambiado con la bomba Parker Commercial serie P.

P21

312-0100-002, 21/31 ESPACIADOR PARA EJE CONTINENTAL, TB-1669

312-1000-200, 21/31 EJE CONTINENTAL, 5/8 -9 DIENTE, AI-1135

312-1133-002, 30 A 30 EJE DE CONEXIÓN PIGYBACK, AF1133

312-1133-003, 30 A 50 EJE DE CONEXIÓN PIGYBACK, 1133 d.C.

312-1135-133, 21/31 EJE CONTINENTAL 1-1/4″-14 DIENTE, AH-1135

312-1135-138, 21/31 EJE CONTINENTAL 7/8-13 DIENTE, AJ-1135

312-1135-152, 21/31 EJE CONTINENTAL 3/4″ ENCHAVETADO, AV-1135

312-1500-400, 21/31 EJE CONTINENTAL 1″ ENCHAVETADO, ED-1135

391-1781-021, LLAVE PARA 1″ EJE, X10-13 (1/4X3/8X1-1/2)

391-1781-045, LLAVE PARA 1-1/4″ EJE, X10-38, (5/16X15/32X1-1/2)

391-2082-071, 21,315 PASADOR

391-2286-004, ENCHUFAR, T1391 391-2585-006, 31 SELLO DE ANILLO, LB-1669-1

391-2685-011, 21/31 ANILLO DE PRESIÓN PARA EJE CONTINENTAL, X97-100

391-2686-063, 21/31/330 ANILLO DE PRESIÓN DEL COJINETE DEL EJE, (ESPIROLOX) X134-206

391-2882-051, 31/51, TIRA DE SELLO DEL BOLSILLO DE LA PLACA DE EMPUJE

391-2883-058, 21/31 SELLO DEL EJE DE LA BOMBA, INTEGRAL, X73-37-16

391-2883-107, 21/31/330 SELLO DEL EJE DE BOMBA CONTINENTAL, X73-37-18

391-2883-119, 21/31/SELLO DEL EJE DEL MOTOR M330, INTEGRAL, X73-50-9

391-2883-126, 21/31/SELLO DEL EJE DEL MOTOR M330, CONTINENTAL, X73-50-11

391-2884-019, 21 JUNTA DEL CUERPO, UB-3006-239

391-3381-040, 21/31 RETENEDOR DEL SELLO, AE-166

P25

391-2686-065, 25/51/350 ANILLO DE PRESIÓN DEL COJINETE DEL EJE, (ESPIROLOX) X134-283

391-2882-051, 31/51, TIRA DE SELLO DEL BOLSILLO DE LA PLACA DE EMPUJE

391-2883-096, C101/25 SELLO DEL EJE DEL MOTOR, X73-50-3

391-2884-021, 25/51/JUNTA DEL CUERPO M350, UB-3006-244

391-3681-001, CONTROLADOR DE EL VOLUMEN, M1391K

391-3784-028, 5/8″ ARANDELA PLANA

P30 P31

391-1401-025, 5/8″ TORNILLO, 5″ 391-1401-089, 5/8″ TORNILLO, 5-1/2″

391-1401-095, 5/8″ TORNILLO, 5-3/4″ 391-1401-090, 5/8″ TORNILLO, 6-1/2″

391-1401-111, 5/8″ TORNILLO, 7″ 312-0100-002, 21/31 ESPACIADOR PARA EJE CONTINENTAL, TB-1669

312-1135-133, 21/31 EJE CONTINENTAL 1-1/4″-14 DIENTE, AH-1135

312-1135-138, 21/31 EJE CONTINENTAL 7/8-13 DIENTE, AJ-1135

312-1135-152, 21/31 EJE CONTINENTAL 3/4″ ENCHAVETADO, AV-1135

312-1500-400, 21/31 EJE CONTINENTAL 1″ ENCHAVETADO, ED-1135

P37

391-1471-051, 1/2″ COJONES 391-2286-004, ENCHUFAR, T1391

391-2883-052, 37/76/P365 SELLO DEL EJE DE LA BOMBA, X73-37-10

391-2883-094, 75 SELLO DEL EJE DEL MOTOR, X73-50-1

391-3681-001, CONTROLADOR DE EL VOLUMEN, M1391K

391-3782-132, 1/2″ ARANDELAS PLANAS

P50 P51

391-1401-025, 5/8″ TORNILLO, 5″ 391-1401-089, 5/8″ TORNILLO, 5-1/2″

391-1401-095, 5/8″ TORNILLO, 5-3/4″ 391-1401-090, 5/8″ TORNILLO, 6-1/2″

391-1401-111, 5/8″ TORNILLO, 7″ 313-1133-001, 51 EJE DE CONEXIÓN, YA-1133

50-SHFTBRG — 391-0381-077; X69-58; 6306-2RS-20

313-1000-300, 51 EJE CONTINENTAL 7/8-13 DIENTE, AD-1135

313-1135-194, 51 EJE CONTINENTAL 1-4″-14 DIENTE, AG-1135

313-1500-400, 51 EJE CONTINENTAL 1″ ENCHAVETADO, AE-1135

391-1451-076, 5/8″ COJONES

391-1781-021, LLAVE PARA 1″ EJE, X10-13 (1/4X3/8X1-1/2)

391-1781-045, LLAVE PARA 1-1/4″ EJE, X10-38, (5/16X15/32X1-1/2)

391-2082-032, 31/330/51/350 PASADOR, X10-99

391-2286-004, ENCHUFAR, T1391

391-2585-009, 51 SELLO DE ANILLO, NB-1669-1

391-2686-065, 25/51/350 ANILLO DE PRESIÓN DEL COJINETE DEL EJE, (ESPIROLOX) X134-283

391-2882-051, 31/51, TIRA DE SELLO DEL BOLSILLO DE LA PLACA DE EMPUJE

P75 P76

5/8 incógnita 127 — 391-1401-025, 5/8″ TORNILLO, 5″

316-1135-147, 76 EJE CONTINENTAL 1-1/4″ ENCHAVETADO, AL-1135

316-1135-148, 76 EJE CONTINENTAL 1-1/4″-14 DIENTE, AS-1135

391-1451-076, 5/8″ COJONES

391-1781-045, LLAVE PARA 1-1/4″ EJE, X10-38, (5/16X15/32X1-1/2)

391-2082-033, 76 PASADOR, SÓLIDO, X10-98

391-2286-004, ENCHUFAR, T1391

391-2584-051, 76 RETENEDOR DEL SELLO, RA-1072

391-2585-011, 76 SELLO DE ANILLO, WB-1669-1

391-2686-025, 76 ANILLO DE PRESIÓN DEL COJINETE DEL EJE, X96-315

391-2881-457, 76 JUNTA TÓRICA DEL RETENEDOR DEL SELLO, L-3006-47

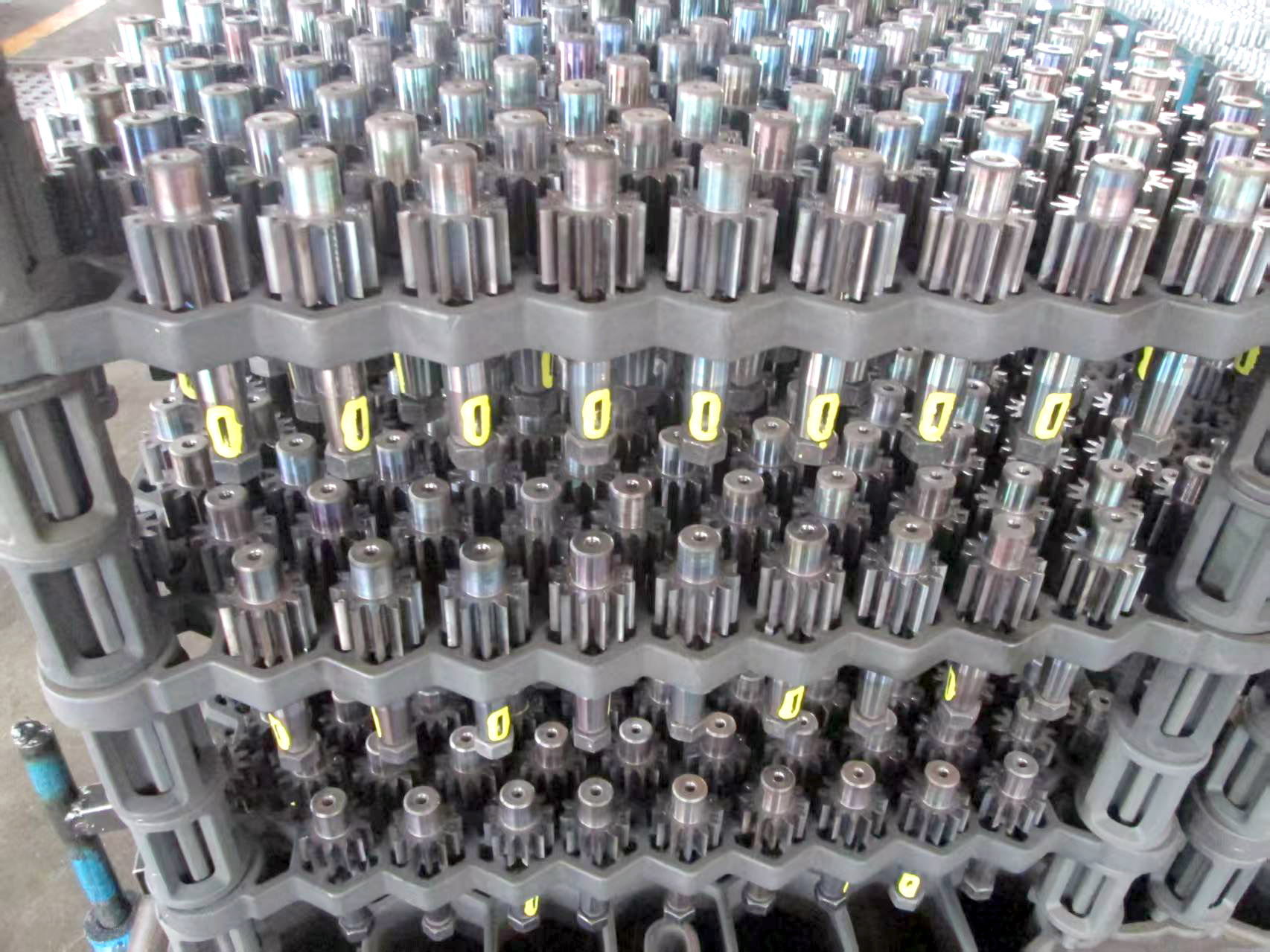

Características clave del equipo Parker

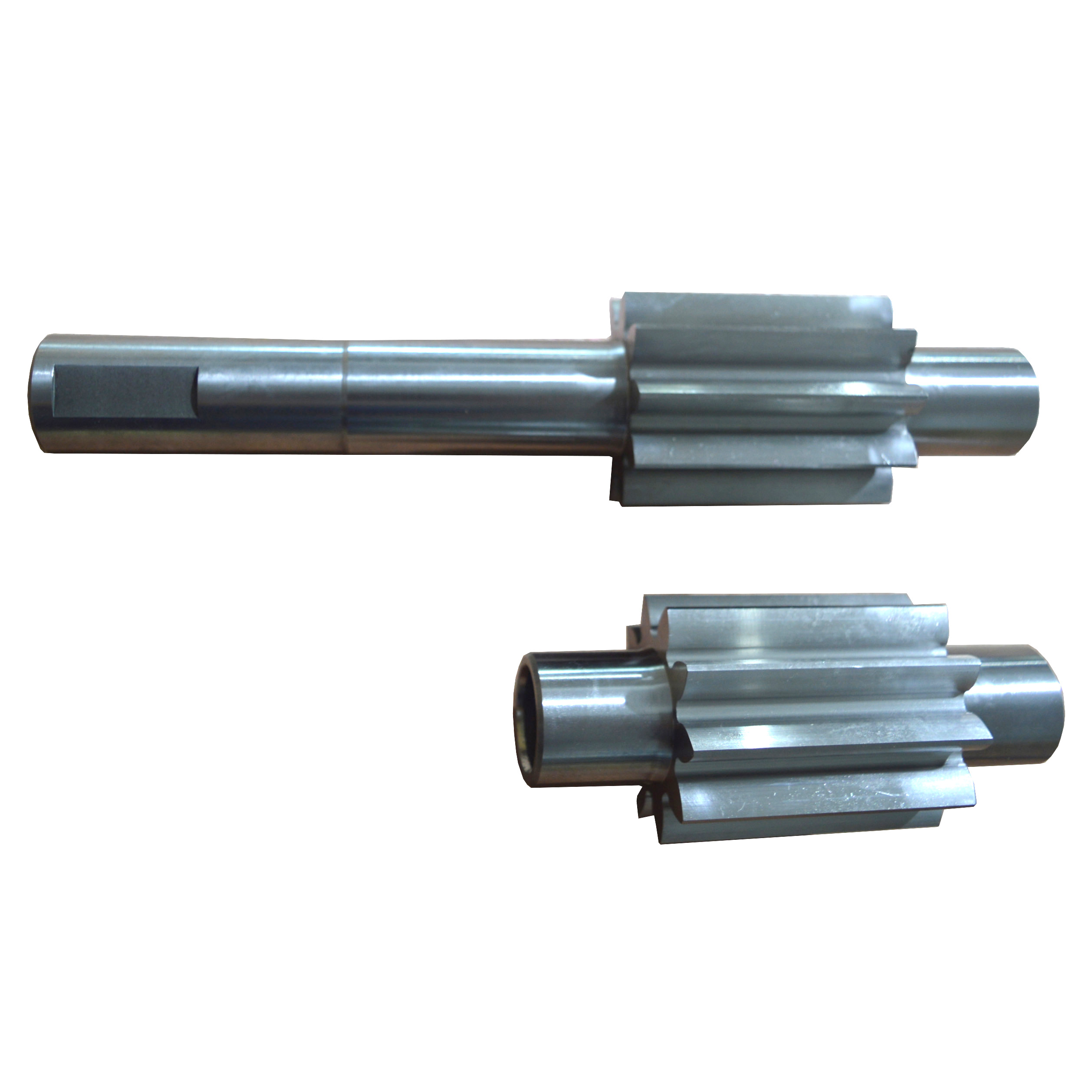

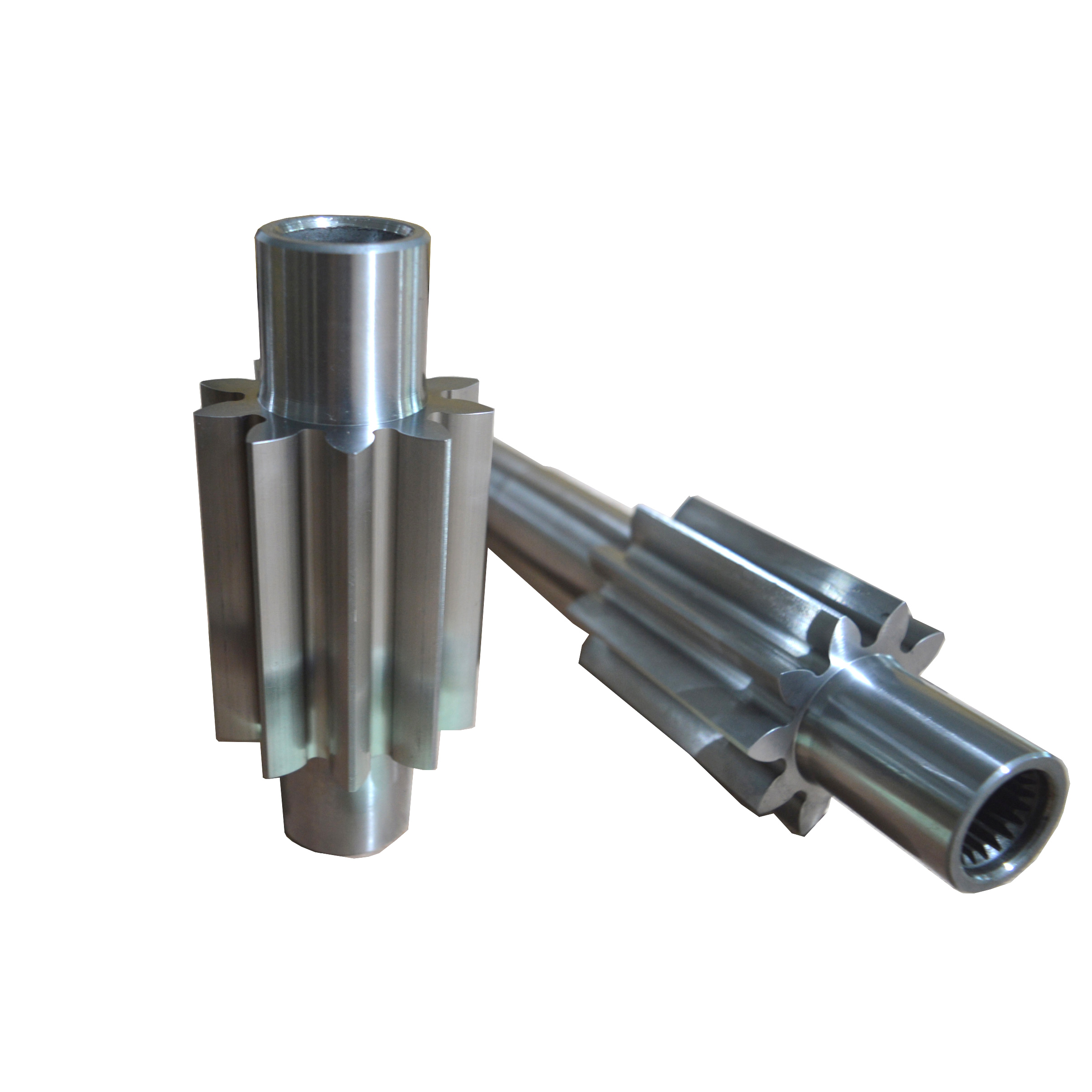

material: 8620Tipos de estrías H/ 20CrMnTi: Splines involutas/splines rectos

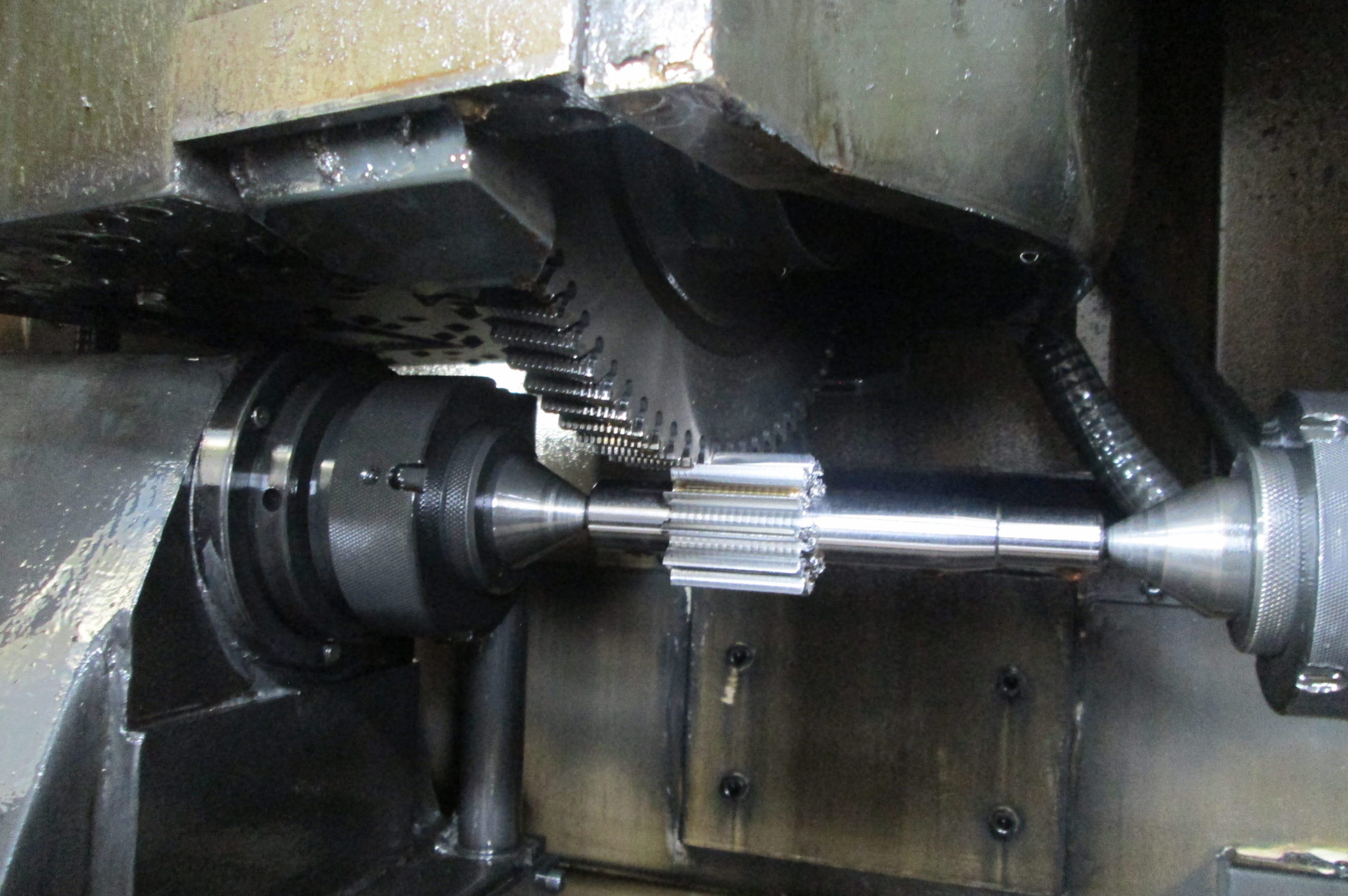

Método de mecanizado: torneado, calefacción y cocción

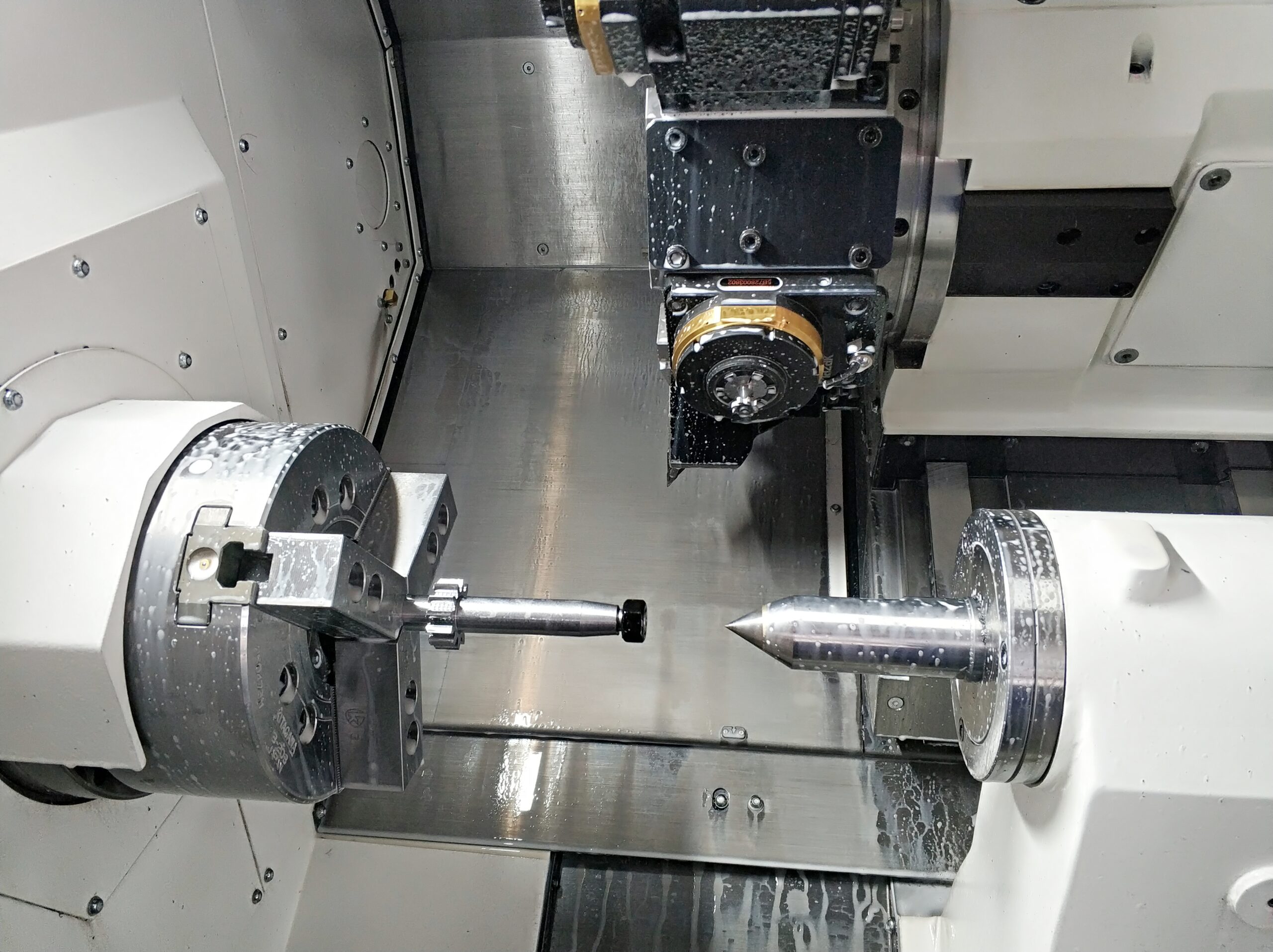

Torneado: máquina de torneado cnc, Obtenga una dimensión específica y una superficie fina.

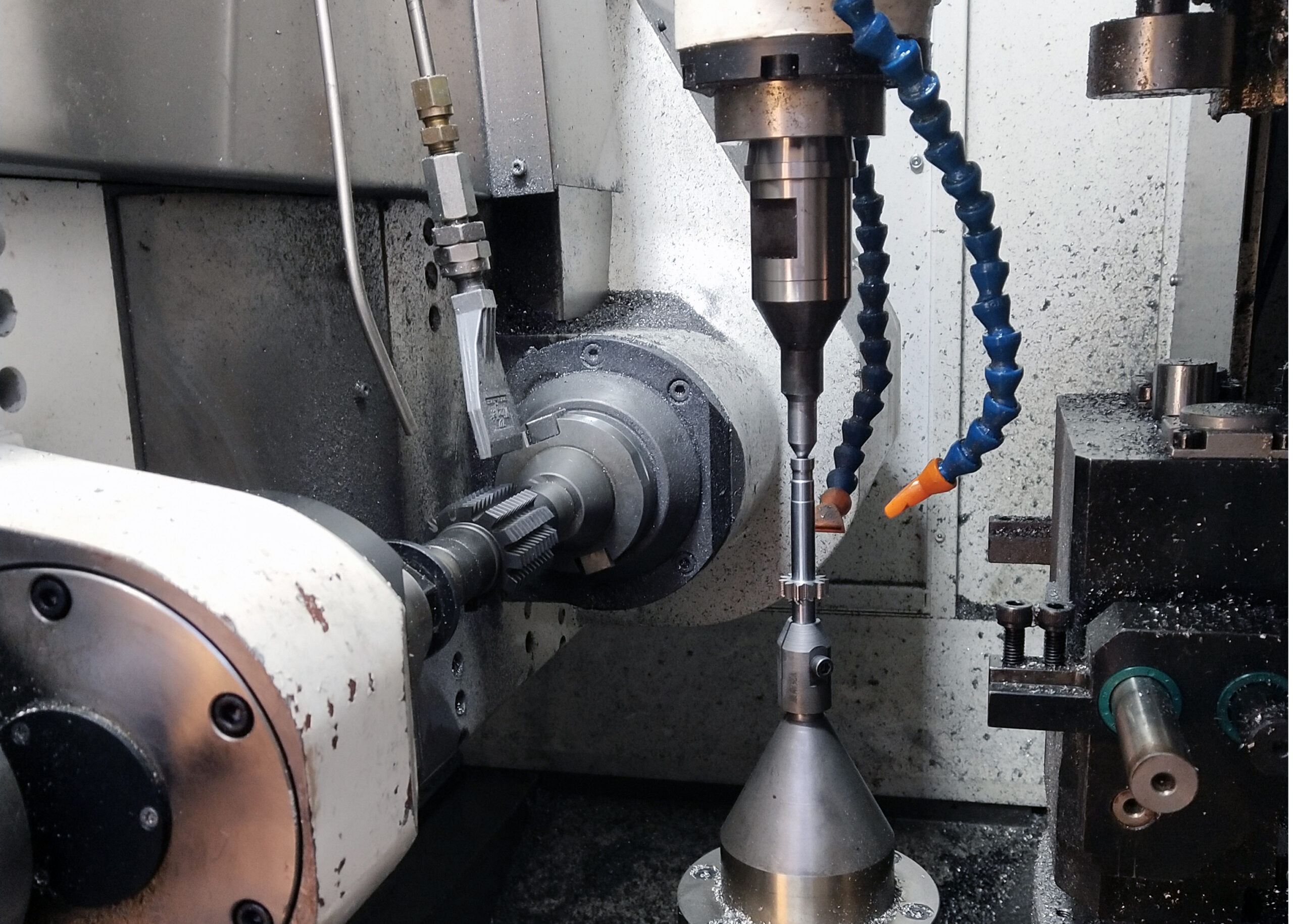

Engranaje: es un método de fabricación de engranajes para cortar los dientes en el blanco con una placa., Todos nuestros pasatiempos y afeitados son automáticos, Asegúrese de una alta precisión del perfil de dientes y el plomo.

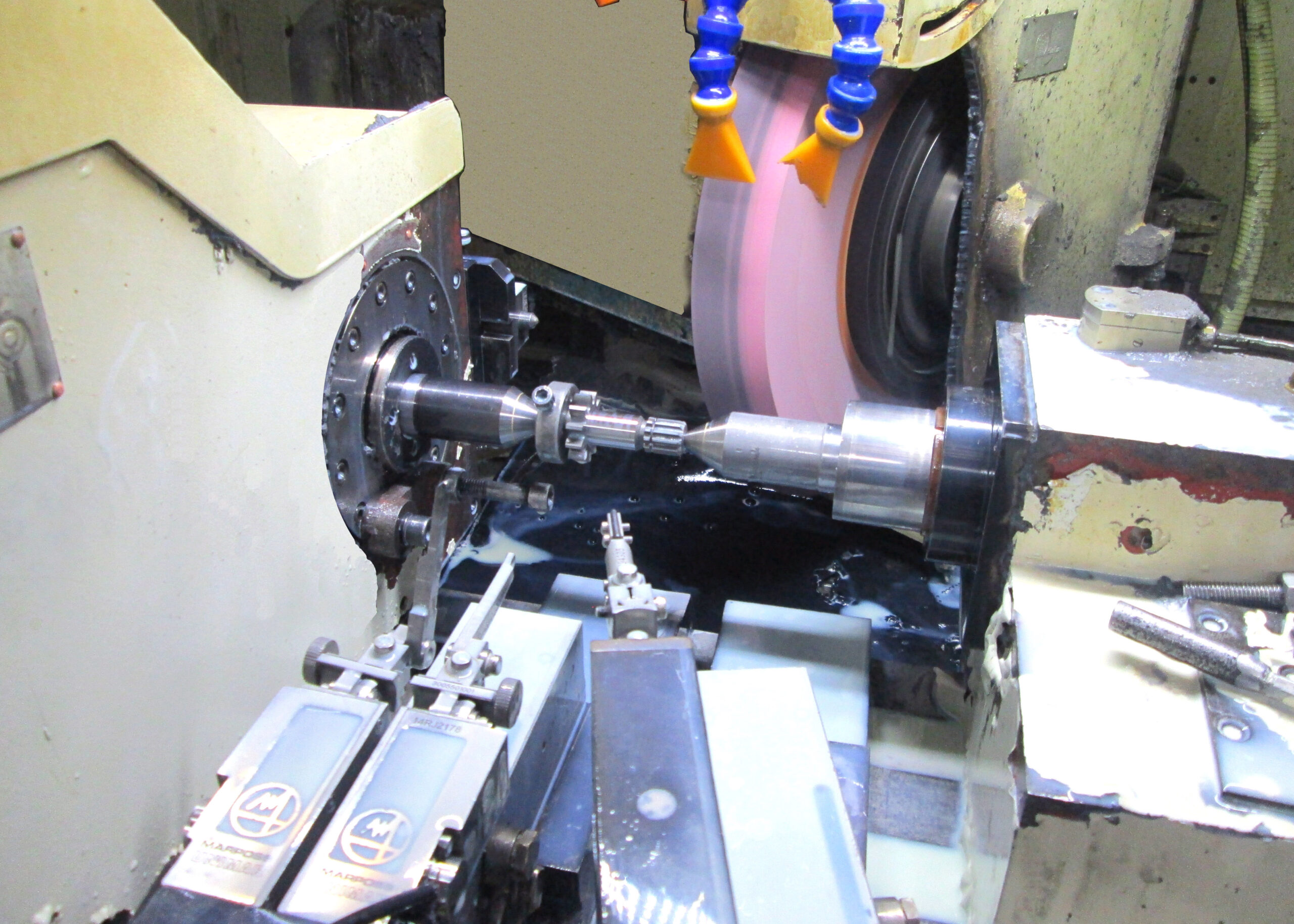

Afeitado de engranajes: Elimina pequeñas cantidades de metal de las superficies de trabajo de los dientes de engranaje. Errores correctos en el índice, ángulo helicoidal, perfil de dientes. El proceso de afeitado de dientes también puede mejorar el acabado de la superficie del diente. El afeitado proporciona modificaciones de forma que reducen el ruido de la marcha. Estas modificaciones también pueden aumentar la seguridad y la vida del equipo..

Tratamiento térmico de engranajes: un paso crítico en la fabricación de engranajes para mejorar la dureza, fortaleza, resistencia al desgaste.

Demanda técnica:Carburación y enfriamiento, dureza 58-64 HRC, profundidad de la caja 0,6-1,0 mm

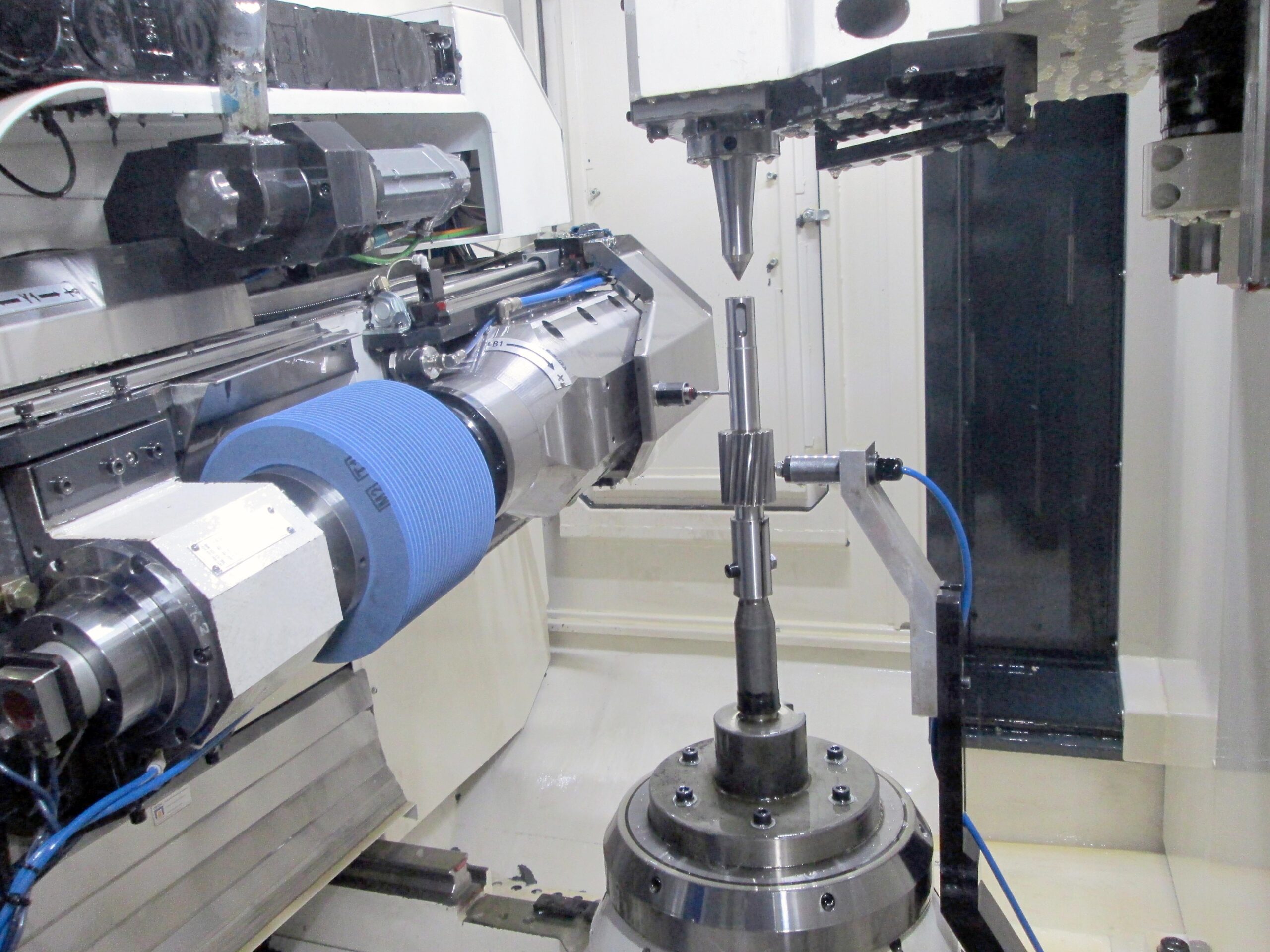

Molienda de engranajes: El rectificado de engranajes es un proceso de mecanizado de precisión que se utiliza para mejorar el acabado de la superficie., exactitud, y durabilidad de los engranajes.

Prueba de engranajes: La inspección de engranajes garantiza la calidad, exactitud, y rendimiento verificando las tolerancias dimensionales, geometría del diente, acabado superficial, y dureza.

| Perfil del diente | Garantiza una forma de involuta correcta para un mallado suave. |

| Precisión de tono | Afecta el engranaje y los niveles de ruido. |

| Sin | Comprueba errores de excentricidad y alineación. |

| Acabado superficial | Impacta la resistencia al desgaste y la vida a fatiga. |

| Dureza & Profundidad del caso | Verifica |